Tech Spotlight Series: Faradine Systems IoT sensors revolutionize information gathering for the military and government

By leveraging the capabilities of remotely monitored Internet of Things (IoT) sensor technologies, the US military can potentially empower tactical operators by allowing them to shift their focus from mundane, repetitive tasks. Instead of traveling to austere environments to check fuel gauges or some other metric that can be monitored remotely, they could concentrate on more mission-critical tasks in austere locations. This is where Faradine Systems comes into the picture.

Performing routine tasks like checking the status of water filters or monitoring fuel gauge levels for generators may appear relatively easy, except when carried out on the battlefield. This conventional approach uses valuable human resources and exposes military personnel to potentially life-threatening situations.

Faradine Systems is at the forefront of developing advanced sensors, IoT devices, and edge computing solutions that bridge gaps between disparate platforms, facilitating remote diagnostic monitoring and feedback.

The Last Mile recently sat down with Chris Mitchell, Founder and Chief Executive Officer of Faradine Systems, to learn more about the company, how Faradine’s product line leverages mobile mesh in off-grid environments, and the company’s compelling current and future projects.

The Last Mile (TLM): Can you tell our readers about Faradine Systems? What does the company do? What kinds of solutions does it offer?

The Last Mile (TLM): Can you tell our readers about Faradine Systems? What does the company do? What kinds of solutions does it offer?

Chris Mitchell: Our relentless pursuit of technological supremacy has led us to develop and deploy unparalleled capabilities in monitoring, diagnostic feedback, and predictive/preventive maintenance notifications.

I founded Faradine Systems in January 2014 as a company primarily working in the demanding space industry. The company developed a novel technology that flew on the International Space Station, SpaceX Dragon capsule, Northrop Grumman Cygnus spacecraft, and Blue Origin New Shepard. During this time, we built a reputation as an organization that could successfully enable remote control and data feedback utilizing data channels that we don’t control. Because of these abilities, we were one of the first civilian companies that SpaceX allowed to have connections on their vehicles.

Eventually, we returned to Earth and began leveraging many of our technologies for industrial users who wanted to monitor their machines and equipment through IoT sensors. Industrial companies – including organizations in the manufacturing industry – were dealing with perceived waste of human capital.

For example, maintaining hydraulic piston pumps, injection molding machines, presses, or any equipment used in a large manufacturing facility involves dispatching a human to interact with the device. Someone often has to measure the machine’s waste with a stopwatch and bucket before manually inputting the data into an Excel spreadsheet. This type of operation identifies dips in performance that might enable them to proactively identify issues with their machines’ health.

Faradine Systems introduced one of its first IoT products, PumpMD, to streamline this process. This device measures the flow off the tap in real-time and uses data analytics from across the entire facility to provide a net health measurement for machines. Ultimately, this eliminated the need to have employees waste time on redundant tasks, which frees them up to focus on more mission-critical tasks.

“The communication issues I faced influenced Faradine and goTenna’s goals for this SBIR Phase 1 contract: to solve the problem of blue and green force tracking for airborne vehicles.” – Chris Mitchell

We’re now looking to leverage our advanced IoT devices to deliver similar results to other sectors and industries, including the government and military. We’re currently working to bring these technologies to bear for the U.S. Department of Defense (DoD).

TLM: How could government agencies leverage these sensors? What government use cases do you envision for these sensor solutions?

Chris Mitchell: The concept for our IoT sensors is to take humans out of the loop without interrupting the ability to gather maintenance data and information.

Any operation conducted in a war zone is a dangerous one. If we send a person to do a mundane job, such as checking on the status of water filters or obtaining a fuel gauge status for generators, we’re risking their lives.

The survivability of tactical operators is the top priority for the DoD, so why not use IoT sensors instead? This allows the military to collect data from the field and gain valuable insights into its equipment without putting soldiers at risk. It also eliminates the need to conduct low-value, repetitive operations, freeing tactical operators to focus on other, higher-value missions.

IoT sensors monitor for invisible threats to the warfighter. The presence of chemical, biological, radiological, and nuclear (CBRN) threat agents could be deadly and nearly impossible for the average soldier to see. IoT sensors can also answer life-saving questions such as, “Has there been a nuclear event, has a chemical weapon been deployed, or are enemy electronic warfare (EW) capabilities approaching?”

TLM: Do you have any examples of current IoT programs being implemented today by the government?

Chris Mitchell: One great example of how the government can leverage IoT sensors is our work with the Centers for Disease Control and Prevention (CDC). The U.S. Environmental Protection Agency (EPA) authorized the release of genetically modified mosquitoes in 2020 to help control mosquito populations and eradicate diseases such as the Zika virus in Florida and Texas. Faradine Systems provided the IoT sensors needed to ensure only male mosquitoes were being released into the wild since male mosquitoes don’t bite, but females do. This system utilizes advanced AI-driven, multi-spectral computer vision to classify and eradicate the target mosquitos by measuring size, shape, and wing speed in near-real-time.

“Our solution is to use our proprietary optical signaling technology to communicate location data to ensure that the aerial vehicles know precisely where their allies are positioned….to more safely deploy ordinance or more efficiently locate them for air evacuations.” – Chris Mitchell

Another example of how the government could leverage our IoT solutions can be seen in our recent work with goTenna – particularly the Small Business Technology Transfer (STTR) submission we recently completed with Eastern Kentucky University. This program involves forward deploying sensors in nature to detect early warnings for natural disasters such as floods – which have plagued the state of Kentucky and Appalachia at large for the past couple of years.

TLM: Faradine recently announced that AFWERX selected it for a Small Business Innovation Research (SBIR) Phase 1 contract. What does this contract involve? What will Faradine be doing on behalf of AFWERX?

Chris Mitchell: I am a combat infantry veteran who completed multiple deployments to Iraq and Afghanistan. I was the guy who always had a radio on me. Even as a young private, maintaining communications with adjacent units was always one of my jobs. However, our equipment rarely worked well enough to provide the level of situation awareness required to complete complex missions. To this day, communicating within and across units is a massive challenge for the military in austere conditions.

This challenge is only getting more significant with the appearance of near-peer adversaries capable of interfering with communications. Now, the military must also worry about intercepting or denying communications entirely, shifting a need for evolving TTPs on the frontlines.

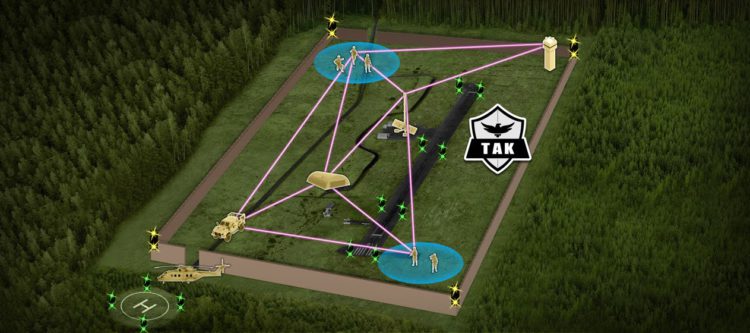

The communication issues I faced influenced Faradine and goTenna’s goals for this SBIR Phase 1 contract: to solve the problem of blue and green force tracking for airborne vehicles. We’re working to enable airborne vehicles to see troops on the ground, identify them, and immediately know if they are allies without radio communication.

One of the areas we’re focusing on is close air support. The Air Force spends millions of dollars training Joint Terminal Air Controllers (JTACs) and Tactical Air Control Parties (TACPs) to help meet this need, but they just can’t be everywhere.

“To this day, communicating within and across units is a massive challenge for the military in austere conditions.” – Chris Mitchell

Our solution is to use our proprietary optical signaling technology to communicate location data to ensure that the aerial vehicles know precisely where their allies are positioned. Every soldier on the ground would carry a device enabling aerial vehicles to more safely deploy ordinance or more efficiently locate them for air evacuations. This type of awareness is an enormously important solution for the U.S. Air Force, Army, and Marine Corps.

TLM: How could the company’s IoT sensors integrate with or utilize mobile mesh networking? What capabilities or functionality do goTenna’s mobile mesh networking technologies bring?

Chris Mitchell: goTenna’s mobile mesh network is widely adopted across the military. With warfighters already leveraging goTenna mobile mesh networking for off-grid communications, we have access to a network that we can use to send signals from our IoT sensors.

The goTenna mobile mesh networking solutions handle all the routing and control for us, extending capabilities beyond the line of sight.

TLM: Why has Faradine Systems chosen to pursue partnering with goTenna? What about goTenna’s solution and the company that made you decide to partner with them?

Chris Mitchell: The capabilities and cost of the goTenna Pro X2 are industry-leading and beyond competitive. The Pro X2’s size, cost, and ability are the perfect “sweet spot” for the goals we want to accomplish.

Additionally, goTenna has a large and vibrant veteran presence that is incredibly important to Faradine Systems. This veteran presence shows goTenna’s commitment to solving real-world problems critical to national security.

On a personal note, I have plenty of friends on active duty, and I know that goTenna is being used where it matters. If we can interoperate with goTenna, the troops on the ground can use our solutions immediately and effectively.

No Comment